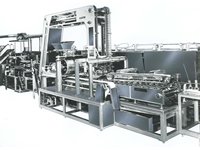

Chikuwa three layers forming machine.

Chikuwa three layers forming machine.

Certainly, there have been different colors of red and white. We put different materials of roes and mustards into Chikuwa, and make the Chikuwa looks like baumkuchen which uses two or three layers to wrap.

It makes Chikuwa easily becomes to have more valuable. The automated system makes the production to have efficiency. We will be happy to help you to develop new markets.

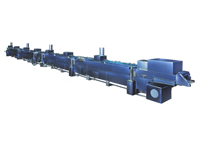

The patent machine -- The Tube Heater Type Frying Machine(YKF-612)

The patent machine -- The Tube Heater Type Frying Machine(YKF-612)

The patent number is No.5414472

The patent number is No.5414472

Advantage of the Tube Heater Type Frying Machine:

Advantage of the Tube Heater Type Frying Machine:

・Newly developed ・ reduce the emissions of CO2 ・ saving energy ・

environmental protection.

・Simplifies the operation procedures.

(There is no the steps of ignite the burner)

・There is no gas pipeline so the appearance looks neat.

(There’s no need to adjust the quantity of gas)

・There is no exhaust pipe. So needn’t to process any exhaust gas.

(consider the global environment).

・Because Heater is an embedded type, so it's high efficiency (Reduce costs).

[The maximum surface temperature of the heater is 300 ℃].

・The Oil temperature was controlled by proportional control (PID), It

won't waste electricity and save energy, And improve the stability of

the oil temperature.

(With the set temperature error is less than 1 ℃).

・With the reduction of the oil exchange frequency, the costs will be

reduced.

(The using life of oil will reach three to four times than the original)

・Thermal efficiency is 70%.

New Type and Traditional Type comparison table

New Type and Traditional Type comparison table

(Both are 2-Fryers Automatic frying Machine)

| |

New type (heating mode) |

Traditional type (gas mode) |

Safe devices

|

・ Don’t use fire, so no worry.

・ There is no worry about oil

spills.

・ There device prevents the empty

burning.

If there is no right amount of oil

in fryers, then the power of

heater won't be opened.

・ There is device prevents

overheat.

The heater will stop when the oil

temperature reaches above a

high temperature (200 ℃).

The operation(setting) can be

easily performed on the

operation panel.

|

・ The burner will have the danger

of catch fire and flameout.

・ There device prevents the empty

burning.

If there is no right amount of oil

in fryers, then the burner can't

be ignited.

・ There is device prevents

overheat.

The main gas valve will become

【Close】state then stop burning

when the oil temperature

reaches above a high

temperature.

The operation(setting) can be

easily performed on the

operation panel.

|

working environment

|

・ Because the simple structure has

no exhaust pipe, so there are no

carbon dioxide emissions.

・ There are no complicated gas

pipelines, so there is no need

to maintain for each device.

|

・ Along with the room

temperature rises, the

incomplete combustion will be

happened and produce smoke

problem.

・ There is the risk of gas leak.

|

Thermal efficiency

|

・ Heater mode.

70-80%.

(Compared with our company)

|

・ Metal mesh gas mode.

30%-35%.

(Compared with our company)

・ Tube burner mode.

27%-33%.

(Compared with our company)

・ Pipe burner mode.

20%-25%.

(Compared with our company)

|

The production capacity

The production capacity

・400Kg/H The power consumption.(The instantaneous maximum is 91Kw)

・The average data are 54.6Kw/H when the machine is running. [Achievements]

※It's only counts power consumption of the heater.

Large type (by W width) electricity consumption and production capacity

(The following data are only for reference)

| Overall Length(m) |

The first vessel (total length) x width (m)

(The conveyor belt is made of stainless steel)

|

The second vessel (total length) x width (m)

(The conveyor belt is made of stainless steel)

|

Electricity consumption

Instantaneous maximum

|

Electricity consumption

Run average

|

Production quantity/ H

(Each product is average 50g)

|

| 7.5 |

3.5 x 0.35 |

2.6 x 0.4 |

47.3Kw |

28.6Kw/H |

4,500 |

| 8.3 |

4.0 x 0.35 |

3.0 x 0.4 |

54.3Kw |

32.8Kw/H |

5,200 |

| 9.3 |

4.5 x 0.35 |

3.5 x 0.4 |

62.1Kw |

37.5Kw/H |

6,500 |

| 10.3 |

5.0 x 0.35 |

4.0 x 0.4 |

70.0Kw |

42.1Kw/H |

7,500 |

3-Vessels type (by particular large width) electricity consumption and production capacity

(The following data are only for reference)

| Overall Length (m) |

The first vessel (total length) x width (m)

(The conveyor belt is made of stainless steel)

|

The second vessel (total length) x width (m)

(The conveyor belt is made of stainless steel)

|

Electricity consumption

Instantaneous maximum

|

Electricity consumption

Run average

|

Production quantity/H

(Each product is average 50g)

|

| 9.3 |

4.5 x 0.5 |

3.5 x 0.6 |

90.9Kw |

54.6Kw/H |

8,000 |

| 10.3 |

5.0 x 0.5 |

4.0 x 0.6 |

102.4Kw |

61.4Kw/H |

10,000 |

| 11.3 |

5.5 x 0.5 |

4.5 x 0.6 |

113.9Kw |

68.2Kw/H |

12,000 |

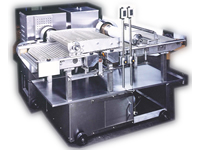

■Automatic CHIKUWA Processing Machine(YKC-105)

Automatic CHIKUWA Processing Machine:

・The YKC-105 features a special mechanism called the "Suwari" mechanism. This mechanism allows the YKC-105 to process even thinner fish paste and ensures efficient, economical work.

【W width type】

・A double width YKC-105 capable of producing 12,000 pieces. 40 gram products per hour is also available.

・The weight error is only ±1.5 grams.

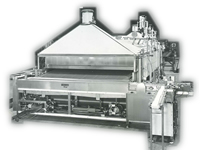

■Automatic SASA-KAMA Processing Machine(YKA-802)

Flat Pasting Machine ( SASA- KAMABOKO, etc.):

Advanced baking machine for baking paste products.

【Specification】

Capacity:40 g×5,000 pieces/H

Roasting time:2 minute

Machine Dimention: W 1.9m×L 20.5m

■Universal TEMPURA Forming Machine(YKT-502)

Universal TEMPURA Forming Machine:

・The YKT-502 forms fish paste into Tempura as if it were formed by hand, and eliminates all the problems associated with ordinary forming machines.

・Size and weight of the products can be adjusted using a handle.

■Exclusive GOBOTEN Forming Machine(YKT-507)

Exclusive GOBOTEN Forming Machine:

・The YKT-507 is designed to form GOBOTEN. A fish paste cake that includes edible burdock in the center. It is also possible to form ordinary fish paste cake.

■KAKI-AGE Forming Machine(YKT-508)

KAKI-AGE Forming Machine:

・The YKT-508 can form a mixture of 30percent fish-paste and 70percent small pieces of vegetables into products called KAKI-AGE. Other Yamasaki Machinery forming machine do not have this function.

■TEMPUPA Oil Extracting Machine (

Air Roll Type

)(YKF-610)

TEMPURA Oil Extracting Machine ( Air Roll Type):

・The used cooking oil is automatically and naturally removed from the front and rear sides of fries through the stainless steel air roll, and stored in the oil tank.

・The transfer conveyor keeps the proper space between the net and the air roll then using the spring elasticity.

・The machine is applicable to fries of any shape, affording a high performance.

・The air roll and the suction hose are of one-touch fitting-removing type. The main body is made of stainless steel.

※Since the used oil is efficiently sucked, the cooling conveyor is least contaminated by the oil.

■Frying Machine (

Tube Burner Type, Tube Heater Type

)(YKF-612,YKF-615)

YKF-612 2-Vessel Frying Machine (Tube Heater Type):

YKF-615 2-Vessel Frying Machine (Tube Burner Type):

・The tube burner heats uniformly the pan bottom indirectly and moderately, therefore always keeping the temperature stable.

・The operations are so easy. Push the buttons according to the directions (voice) of the machine. The tube burner utilizes waste heat after combustion. This ensures high thermal efficiency and clean atmosphere in the factory.

■Frying Machine (

Pipe Burner Formula Type

)(YKF-603)

2-Vessel Automatic Frying Machine:

・The YKT-603 is extremely efficient, economical, and easy to maintain.

・An oil filter provided.

■Cooling Machine(YKS-910)

Cooling Machine (with Washer):

・This cooling machine rapidly cools the products loaded from an alignment machine while transferring them. Also this cooling machine has been designed to save energy.

・The washer provided with this machine keeps the transfer net clean.

・Even if the products are loaded in an irregular manner, with one product on another, they are cooled uniformly.

・Hot water generated in the piping outside this machine is injected with high pressure from the spray nozzle onto the inside and outside surfaces of product transfer net. Thus adhered product refuse and oil are removed from both sides of transfer net. The washer washes the net and also dries it.

■Automatic Steaming Machine(YKL-706)

Automatic Steaming Machine ( Chuko Flow Belt Type):

・The versatile YKL-706 features all the functions required of automatic steamer. It dramatically boosts business efficiency.

・A washer is also provided to ensure cleanliness.

Boiling Tub (Hanpen, Tsumire):

・By varying the temperature, the YKF-601 can be used for a variety of applications. The proportion control system keeps the temperature stable at all times to produce homogeneous products. A temperature recording machine can be installed optionally. The YKF-601 is easy to maintain.

Chikuwa three layers forming machine

Chikuwa three layers forming machine

Chikuwa three layers forming machine.

Chikuwa three layers forming machine.  The patent machine -- The Tube Heater Type Frying Machine(YKF-612)

The patent machine -- The Tube Heater Type Frying Machine(YKF-612) The patent number is No.5414472

The patent number is No.5414472

Advantage of the Tube Heater Type Frying Machine:

Advantage of the Tube Heater Type Frying Machine: New Type and Traditional Type comparison table

New Type and Traditional Type comparison table The production capacity

The production capacity